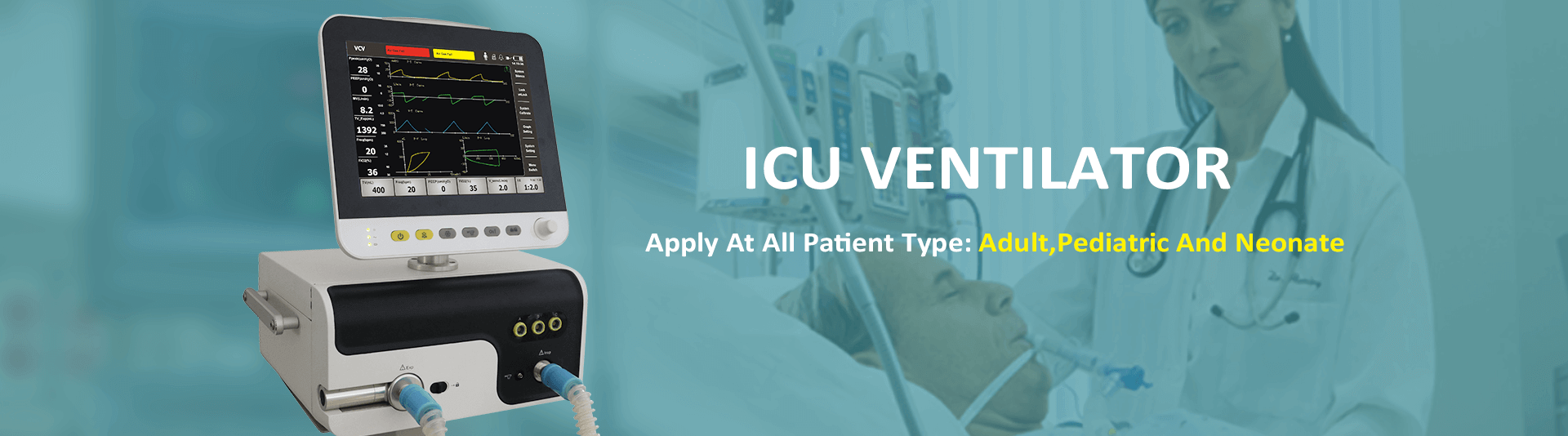

How to Maintain Hospital Ventilator Machine?

The daily maintenance of the hospital ventilator machine is the most important thing for our health. So do you know how to maintain it? Follow a professional Hospital Ventilator Machine Exporter to find out.

Anesthesia Ventilator

Before using the Hospital Ventilator Machine every day, please do the following:

①Power check: check whether the power supply matches the rated voltage calibrated by the ventilator, and then check whether the main unit, air compressor, humidifier, etc. are connected to AC power.

②Gas source inspection: check oxygen, air source is in the normal range (280-650Kpa).

③System self-test: conduct air leak test and pipeline compliance test, check machine leakage and machine working status.

④Common leak points: the exhalation valve assembly is not assembled in place after disinfection; the oxygen battery is not installed in place; the humidification tank is filled with water; the pipeline sampling port is not sealed; and the patient balloon is not inflated.

⑤Check whether the humidification liquid in the humidification water tank is sufficient, ensure that the liquid level of the humidification liquid can not be lower than the lowest water level line, and cannot exceed the maximum water level line. The humidification water tank should be disinfected regularly according to the instructions of each manufacturer. It is recommended to change the water every day. And when you don't use it, you should pour out the water inside to prevent bacteria and viruses from breeding.

⑥Flow sensor should be soaked in 75% alcohol for about one hour, thoroughly dry in the air for 30 minutes. Do not use pressure cooker or steam disinfection; do not rinse; do not dry.

⑦Pipelines, masks are regularly replaced and disinfected.

Daily maintenance of the ventilator:

①To ensure the accuracy of oxygen concentration detection, the oxygen sensor needs to be calibrated regularly. It is recommended to perform oxygen concentration calibration when the oxygen concentration setting value deviates from the actual monitoring value by more than 3%.

②In order to ensure the accuracy of tidal volume detection, the flow sensor needs to be calibrated regularly. It is recommended to perform user flow calibration when the tidal volume setting value deviates from the actual monitored value by more than 10%.

③Air compressor inlet filter is recommended to clean weekly to ensure smooth air inlet.

④After atomization, both the tubing and the exhalation valve assembly need to be cleaned to prevent the drug from corroding the flow sensor, causing measurement errors.

⑤The gas source inlet water cup is drained regularly. If there is more water, please drain it in time.

English

English  French

French  Chinese

Chinese  Spanish

Spanish