How to Quickly Detect the Quality of Anesthesia Machine?

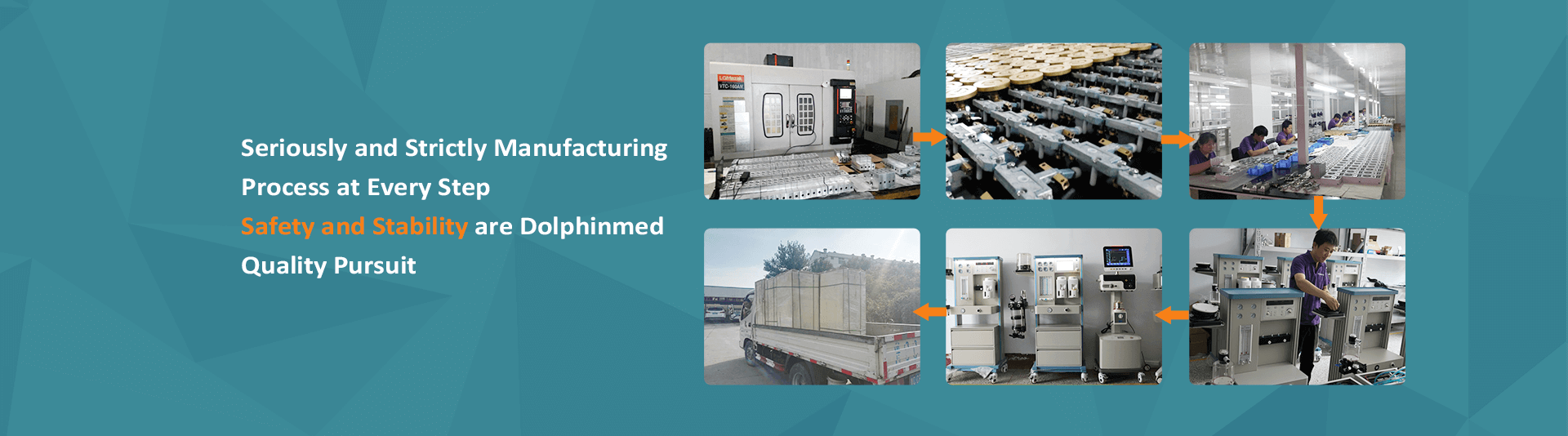

As a Gas Anesthesia Vaporizer Manufacturer, let's share with you how to quickly detect the quality of an anesthesia machine.

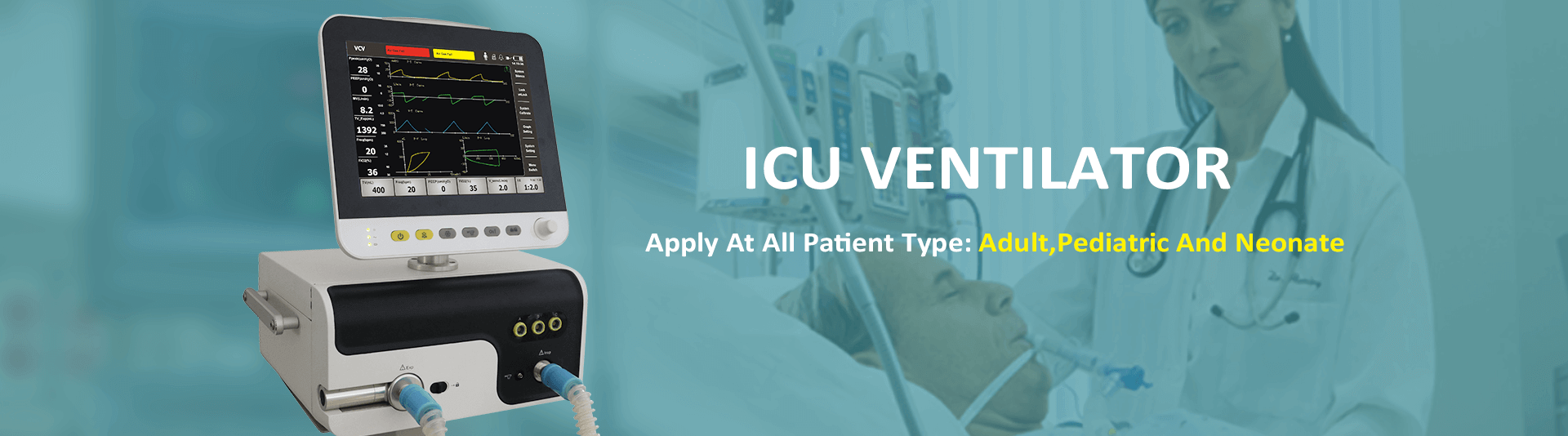

In the actual detection of the anesthesia machine, it is particularly necessary to pay attention to the setting of environmental conditions and test conditions, which will directly affect the detection results and detection efficiency. For example, when performing tidal volume detection, the respiratory rate is generally VT<300ml. Can be set to 30-40 times / min; VT> 500ml, the respiratory rate can generally be set less than 20 times/min; VT > 700ml, the respiratory rate can generally be set less than 10 times/min; especially the tidal volume is set 500ml, when the respiratory rate is 16-18 times/min, it is a parameter that is very commonly used in clinical practice. During the detection process, the working performance of the anesthesia machine can be detected when setting this parameter.

The error of each indicator for detecting ventilation parameters is calculated according to the formula in the specification and judged whether it is qualified or not. If any of the above alarms fail during the alarm check, the item is unqualified. If the airway pressure, ventilation, and suffocation alarms are unqualified, the anesthesia machine fails to pass the test; if the power supply test and alarm are unqualified, the equipment is available. But it must be restored as soon as possible.

China Medical Anesthesia usually tests once a year. If the frequency of use of the equipment is too high, it should be semi-annually. For equipment that fails to pass the test, it is immediately deactivated and repaired. For testing qualified equipment. Paste the qualified label and calibrate the next detection time, paying special attention to all parameters.

After the end of the test, the parameters of the anesthesia machine should generally be restored to the state before the test for clinical emergency use.

English

English  French

French  Chinese

Chinese  Spanish

Spanish