Repair and Maintenance of ICU Ventilator

ICU ventilator can be said to be one of the largest numbers of departments in every hospital. It is extremely important to keep the ventilator and carry out reasonable maintenance in the department so that it can maximize its function and extend its service life to serve the majority of patients. Today we will talk about how to maintain and maintain it.

1. Lack of origin

Lack of air source is a very common fault. If the pressure is less than 0.2MPa, it means that there is a shortage of air source. At this time, not only the air path of its host needs to be checked, but also the specific conditions of the air compressor. In order to eliminate the fault, if the water filter function of the ventilator or the air compressor is leaking, it is very likely that agglomeration will occur during compression, which will cause the air compressor to block and cause obstacles. In the process of use, it should be specially dispatched The personnel regularly check the specific conditions of the air compressor, and timely check and replace the aging and damaged accessories, so as to effectively avoid this failure and ensure the use effect and safety of ICU ventilator

2. Air leak failure

Leakage failure is the most likely failure. At this time, maintenance personnel should detect it in time (ventilation, sensors, etc.) and take timely measures. If it has a fault with indicator deviation during use, the maintenance personnel can replace the sensor to eliminate the fault, or clean the sensor to correct the fault, and check whether the connecting pipes between the various parts of the ventilators are smooth and whether there is condensation If there is water phenomenon, if there is water condensation, it is necessary to take timely treatment measures to fully avoid indicator deviation faults.

3. The self-check of the ICU ventilator failed

The self-check of the ventilator failed. The most typical case is that the test result of the oxygen solenoid valve is abnormal, and the self-test fails. If this abnormal situation occurs, it will not operate normally and cannot work. It is necessary to have a sufficient grasp of the EST self-inspection steps and related procedures and operations before entering the oxygen chamber, otherwise, the effect of troubleshooting and getting twice the result with half the effort will not be achieved.

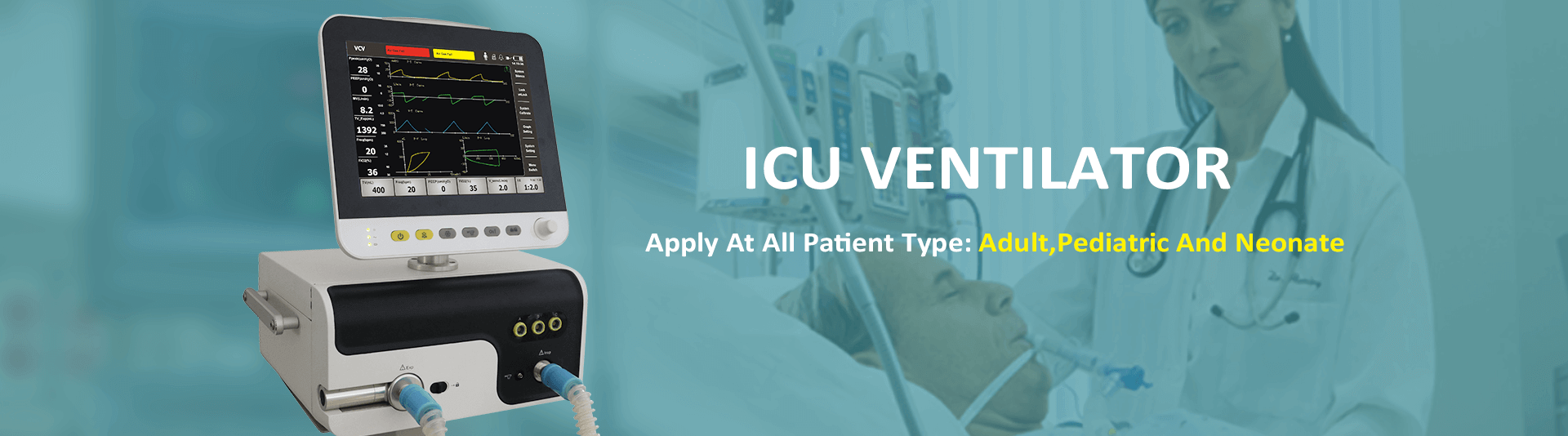

ICU Ventilator

4. Shutdown failure

The typical fault that causes the most damage is the shutdown fault. Although the types of ventilators are different, the principles are similar. If there is a shutdown failure, on the one hand, it will cause a certain degree of damage to the machine, speed up its damage, etc.; on the other hand, it will also bring a certain degree of danger to the patient used, and in severe cases, it will threaten their life. A problem with the power supply is a very typical cause, and the second major cause is a failure inside it.

5. PEEP unqualified

Respirator self-test PEEP failure. If the self-test test of the ICU ventilator fails, it means that many functions of the ventilator have failed, and the relevant maintenance personnel needs to analyze the error code effectively, and at the same time, conduct regular inspections and maintenance of the instrument.

Eliminate the fault, so as to ensure the safety and effectiveness of the patient in the process of using the instrument for treatment, so as to protect their life and health.

6. Daily maintenance of it

The ventilator has its own life cycle, so it needs to be repaired daily after use. The daily maintenance work includes timely replacement of the filter and other related accessories to avoid malfunctions due to auxiliary accessories and ensure that it is in use Can operate normally. Check-in time whether the components are connected smoothly, whether there are aging components, and replace them in time. Regularly check the function of the ventilator to ensure that its performance is normal.

After the replacement, a self-check is required to ensure that there will be no air leakage in the connection, and the setting parameters need to be adjusted after completion. If a failure occurs during the self-inspection, it should be repaired in time. If the ventilator alarms when it is turned on, it means that the ICU ventilator is already malfunctioning. At this time, the self-check should be performed first, and then targeted maintenance. Normally, the alarm occurs when the machine is turned on, all due to the clogging of its pipeline. At this time, the filter can be removed and cleaned, and then the self-inspection can be performed.

The above troubleshooting and maintenance of the ventilator, maintenance of the ventilator is a skill that must be proficient. For more details. please ask us --the Ventilator Supplier.

English

English  French

French  Chinese

Chinese  Spanish

Spanish